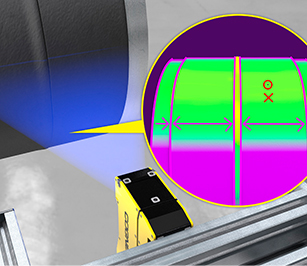

What is Edge Learning?

Edge Learning is a branch of AI that processes data directly on the device where it originates, eliminating the need for centralized processing. It is fast, easy to set up, and requires fewer images for training compared to Deep Learning solutions. It is ideal for engineers of all levels looking to integrate automation into their production lines without advanced AI expertise.

8441124288

8441124288

844 278 5462

844 278 5462