LOCTITE® Mexico

We are a Texas-based distributor of national and international LOCTITE® products.

Request a quote ▸

LOCTITE® is a global leader in adhesives, fasteners, sealants, and surface treatments, offering technologies such as anaerobic, acrylic, cyanoacrylate, epoxy, hot melt, silicone, urethane, and UV curing.

LOCTITE Products

LOCTITE Adhesives

A wide range of products designed for high-stress resistance, impact absorption, flexibility, gap filling, and more. They ensure strong, reliable bonding while preventing loosening, corrosion, and breakage.

View ProductsLOCTITE Lubricants

Enchance friction protection, reduce wear, and prevent overheating.

View ProductsLOCTITE Sealants

Ideal for both low- and high-strength applications, effectively filling gaps in threaded parts and providing instant sealing at low pressure

View Products

LOCTITE Vacuum Impregnation

Improve the quality of your castings with LOCTITE®'s permanent sealing technology, eliminating porosity, cracks, and leaks in engine blocks, transmissions, pumps, and more.

View Products

¿Need personalized LOCTITE® Support?

Get in touch with our team of chemical supply experts to find the perfect LOCTITE® solutions tailored to your needs

Request a quoteLOCTITE: Your Best Choice

A leading company dedicated to research and development, offering solutions for a wide range of industrial processes and production lines.

Benefits of LOCTITE Products :

- · Superior adhesion performance.

- · High-quality and durable for industrial applications.

- · Highly effective for final finishes.

- · A wide range of technologies to meet diverse market needs.

- · Continuous innovation to optimize production lines.

- · Long-lasting bonding of various components.

- · Resistant to extreme temperatures and impacts.

¿Why Choose LOCTITE??

For over 60 years, LOCTITE has been helping businesses enhance reliability, reduce downtime, and improve manufacturing processes. As a trusted LOCTITE distributor, Vinssa offers high-performance adhesives, sealants, and coatings designed for the most demanding design, production, and maintenance challenges.

Advantages of LOCTITE Industrial Adhesives

LOCTITE adhesives are a superior alternative to mechanical fastening methods for nearly all applications:

- Bonds a variety of substrates, including plastics and metals.

- Provides strong, flexible joints.

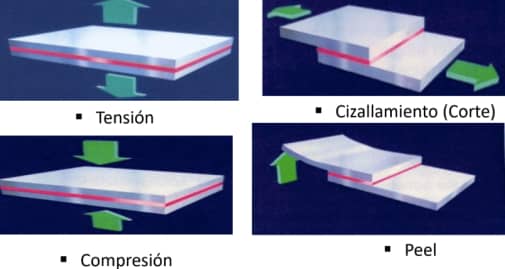

- Ensure even stress distribution.

- Fills large gaps.

- Seals, bonds, and protects components.

- Enhances reliability and quality.

- Prevents deformations.

- Withstands a wide range of temperatures.

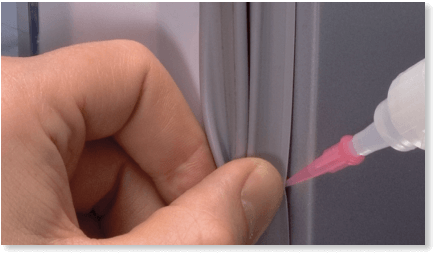

- Easy to apply.

Explore Our Latest Projects with Industrial Chemicals

Download Success Story

Download Success Story

Benefits of Using LOCTITE Adhesives

- Even stress distribution ,enhancing both static and dynamic strength.

- Flexibility in designing joints with various substrates.

- Easily integrates into automated manufacturing.

- Improves aesthetics compared to other bonding methods.

- Reduces weight, making it, ideal for lightweight structures.

- No surface changes or texture alterations.

- Lowers overall production costs.

- Acts as a sealant, preventing pressure loss, water penetration, and corrosion.

- Forms an insulating layer to prevent galvanic corrosion and acts as both an electrical and thermal insulator.

Comparison of LOCTITE Bonding Methods

| Mechanical Fastening | Thermal Bonding | Adhesive Bonding |

|---|---|---|

| Joints can loosen over time | Cannot be disassembled | Bonds permanently or temporarily |

| Requires drilling into substrates | High temperatures creat mechanical stress | Ensures even load distribution |

| Susceptible to galvanic corrosion | Suitable only for homogeneous materials | Bonds different materials with ease |

| Requires excess material inventory | Often results in unattractive joint lines | Reduces component count and simplifies design |

Mechanical: Joints can loosen over time

Thermal: Cannot be disassembled

Adhesives: Bonds permanently or temporarily

Mechanical: Requires drilling into substrates

Thermal: High temperatures creat mechanical stress

Adhesives: Ensures even load distribution2

Mechanical: Susceptible to galvanic corrosion

Thermal: Suitable only for homogeneous materials

Adhesives: Bonds different materials with ease

Mechanical: Requires excess material inventory

Thermal: Often results in unattractive joint lines

Adhesives: Reduces component count and simplifies design

How to select the right LOCTITE adhesive?

Choosing the correct LOCTITE adhesive depends on several key factors:

Substrates- Materials you will use

- Surface pre-treatment

- Application method

- Process times

- Curing time

- Process considerations

- Technical requirements

- Load types

Properties and Characteristics by LOCTITE Technology

| Cyanoacrylates | Epoxies | Hot melts | UV Curing | Silicones | Elastomers | Urethanes | Two-part Acrylics | Two-step Acrylics | |

|---|---|---|---|---|---|---|---|---|---|

| Benefits | Wide range of bonding applications and ease of use | Wide range of formulations | Versatile, fast, great gap filling | Fast curing and adhesion to plastics | Excellent temperature resistance | Flexible, paintable, and sealing | Excellent toughness and flexibility | Excellent impact resistance and flexibility | Good impact resistance / no mixing |

| Limitations | Low resistance to polar solvents | Mixing required | Limited heat resistance | Curing equipment required | Low adhesion strength | Low-temperature resistance | Moisture-sensitive | Mixing required | Primer required |

| Benefits | Limitations | |

|---|---|---|

| Cyanoacrylates | Wide range of bonding applications, easy to use | Lower resistance to polar solvents |

| Epoxies | Broad formulation variety, strong durable bonds | Requires mixing before application |

| Hot melts | Versatile, fast, great gap filling | Limited heat resistance |

| UV Curing | Fast curing great adhesion to plastics | Curing equipment required |

| Silicones | Excellent temperature resistance | Lower adhesion strength |

| Elastomers | Flexible, paintable, effective sealing | Low-temperature resistance |

| Urethanes | Exceptional toughness and flexibility | Sensitive to moisture |

| Two-part Acrylics | High impact resistance and flexibility | Mixing required |

| Two-step Acrylics | Good impact resistance / No mixing needed | Primer required |

LOCTITE in the Automotive Industry

Reliable Solutions for Electric Vehicle Charging Infrastructure

Electric vehicle (EV) chargers - from home-use single-phase units to DC fast chargers- demands long-lasting performance, outdoor durability, and safety under all conditions.

LOCTITE materials ensure consistent performance by: - Sealing and protecting electronic components against moisture, dust, and contaminants. - Enhancing efficiency with thermal interface materials that manage heat and improve energy conversión. - Providing durability throught potting compounds that encapsulate and shield connectors - Boosting productivity with adhesives designed for high-speed, reliable assembly Together, these solutions deliver dependable EV charging, inspiring user confidence and ensuring long-term system reliability.

Thermal Solutions for Electric Vehicle Chargers

EV chargers operate at high voltages- up to 500V for DC fast chargers and 800V for ultra-fast chargers- making thermal management critical. LOCTITE thermal interface materials efficiently dissipate heat while meeting safety insulation standards for secure and reliable performance.

SONDERHOFF Foam Sealing

SONDERHOFF's molded-in-place foam sealing (FIPFG) offers: - Automated, adaptable application for varying housing designs - Strong adhesion to diverse surface - Adaptable curing mechanisms - Resistance to extreme temperatures: -55°C to 150°C Perfect for manufacturers seeking high-volume production efficiency and superior environmental protection

Connection Solutions for EV Chargers

LOCTITE threadlockers secure fasteners while allowing future disassembly - an ideal solution for EV charing equipment. Benefits include:, - Preventing vibration-induced loosening - Sealing against moisture, liquids, and corrosion - Maintaining bolt and stud integrity over time

Key Industries

LOCTITE® is a global leader in adhesives, fasteners, sealants, and surface treatments products, providing high-efficiency, durable, and resistant adhesives.

METALWORKING

- Thousands of applications across numerous manufacturing processes.

- Prevent oxidation or seizing of assemblies with LOCTITE.

- Assembly of metal component products.

- Increased fastener retention and reduced vibration-induced movement with LOCTITE.

- High-performance sealing, adhesion, and coating solutions for industries worldwide.

- We provide solutions for all types of applications, from airplanes to furniture.

- Specialists in process optimization and cost reduction through high-performance product development.

ELECTRONICS

- Henkel is the leading supplier of materials for electronic assembly and semiconductor packaging industries.

- LOCTITE solutions specialize in the automotive and home appliance industries.

- Advanced formulations for electrical interconnection that provide structural integrity, critical protection, and heat transfer for reliable performance.

- A wide range of encapsulation (potting) products.

- Durable and resilient assembly with adhesives capable of withstanding high and low temperatures.

- Bonding of extremely thin and critical components in the electronics industry.

AUTOMOTIVE & TRANSPORTATION

- Weight reduction in automotive assemblies by replacing mechanical fasteners with adhesives.

- Increased assembly speed of parts.

- Noise reduction in vehicles.

- Inventory reduction by eliminating components such as gaskets and seals.

- Many of our products are OEM-approved and meet military standards.

- LOCTITE provides design, development, manufacturing, and maintenance solutions for automobiles, aircraft, trucks, and transportation systems.

- High-performance sealants and adhesives for lightweight and advanced constructions with lower fuel consumption.

- Customized solutions for profitable and environmentally responsible operations.

MEDICAL LINE

- LOCTITE’s technical expertise and constant innovation enable significant advances and novel designs for medical devices.

- LOCTITE offers a wide variety of medical tapes, including solvent-based acrylic adhesives, water-based acrylic adhesives, and UV acrylic adhesives with excellent adhesion and skin-friendliness.

- Excellent anchoring for various supports used in medical applications and good breathability.

- LOCTITE ensures consistency and quality in the pharmaceutical industry, ensuring transdermal patches adhere and administer medication as designed.

- Reliable and proven assembly solutions for the medical electronics industry, including conductive adhesives and inks, encapsulation, underfill, soldering materials, and film.

- Used in cardiac and neurostimulation devices, moisture detection sensors, ECG, and TENS electrodes.

- Adhesive materials comply with hygiene standards in the medical community.

- Adhesives for human-contact medical equipment such as syringes.

- Materials meeting ISO-10993 biocompatibility requirements for healthcare products, surgical instruments, and pre-surgical models.

AIRCRAFT MAINTENANCE

- LOCTITE is a leading manufacturer of structural adhesives and surface treatments, with over 50 years of experience in the aerospace industry, offering maintenance solutions for OEM and MRO.

- Henkel invests heavily in R&D for its Bonderite and LOCTITE products to help users successfully address maintenance needs.

- Innovative materials provide practical, economic, and performance benefits through a global distribution network.

- These solutions comply with the strictest industry regulations.

- Lighter assemblies by replacing mechanical fasteners with adhesives.

- Stronger bonds with long-lasting fixation.

- Certified products meeting industry standards.

- Noise reduction during operation.

¿What is LOCTITE and What is It Used For?

LOCTITE® - a trusted brand by Henkel- delivers industry-leading adhesives, sealants, and surface treatment solutions designed for strength, durability, and performance.

The Unstoppable Power of Man and Machine

LOCTITE® is the world’s leading brand in adhesives, sealants, and surface treatment products. From manufacturing to maintenance, LOCTITE® products bond, seal, and protect components in even the most demanding industrial environments- unlocking the unstoppable potential of man and machine.. Learn more about our extensive range of products for the most demanding industrial applications.

LOCTITE®: Solutions for Industry´s Toughest Bonding and Sealing Challenges

Combining innovation and technology, LOCTITE provides essential solutions for countless industrial applications. It is a market leader today and continues to build future markets through its trusted brands in adhesives, sealants, and functional coatings.

LOCTITE®- Frequently Asked Questions

What materials can LOCTITE® bond?

With LOCTITE, you can bond materials such as rubber, plastics, metals, wood, paper, leather- and more!. If you´re working with a special material, contact us for expert advice.

What is LOCTITE?

LOCTITE® is a global leader in adhesives, threadlockers, and sealants. It specializes in anaerobic, acrylic, cyanoacrylate, epoxy, silicone, urethane, and UV-curing technologies. Its advanced formulas optimize manufacturing, improve reliability, and reduce costs across industries like automotive, aerospace, electronics, medical, and more If you have a specific requirement, contact us, and we will be happy to assist you.

¿What is LOCTITE used for?

LOCTITE is used to bond, seal, and coat components in industrial, automotive, and electronic applications - anywhere strong, durable connections are needed. If you have a specific need, contact us, and we will gladly help you bring your project to life.

What types of LOCTITE products are available?

There is a LOCTITE product for every application, depending on your needs. Its lineup includes adhesives, lubricants, sealants, threadlockers, and coatings for every industry.

How do I choose the right LOCTITE product?

Selection depends on material type, application method, curing time, and your project´s performance requirements. LOCTITE® products span the automotive, electronics, metalworking, home appliances, aerospace, construction, medical and more industries. Need Help? Our experts are ready to guide you!

What is the most popular LOCTITE product?

LOCTITE 495 is our most popular adhesive. It is a transparent, colorless, low-viscosity ethyl-based adhesive with fast curing (5 to 20 seconds). It can bond a wide range of materials, including plastics, rubber, and metals. It is available in 20 g, 90 g, and 454 g packaging. If you have a requirement, contact us, and we will be happy to assist you.

How much do LOCTITE products cost?

LOCTITE prices depend on several factors, including the product type, the quantity purchased per month, and the shipping destination. Reach out to our specialists for fully personalized advice, and together, we can help bring your project to life.

How can I find a LOCTITE distributor in Texas?

At Vinssa, we are an authorized distributor with multiple locations across Texas. We have specialists available to help you choose the ideal product for your application. Contact us, and we will connect you with the nearest branch and provide personalized assistance.

What are the advantages of LOCTITE industrial adhesives?

LOCTITE industrial adhesives seal, bond, and protect components, improving product reliability and quality. They do not cause deformations, are easy to apply, and offer flexibility while bonding materials such as plastics and metals. LOCTITE offers a solution for every bonding challenge. Henkel is a leading brand in the industry with extensive experience, and together with Vinssa, we provide the most efficient technical support and service in Texas.

8441124288

8441124288

844 278 5462

844 278 5462