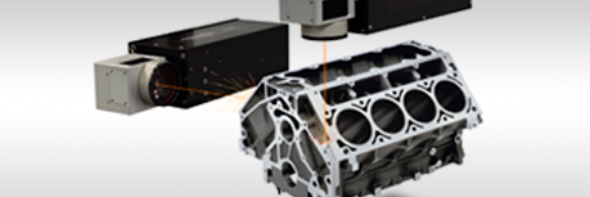

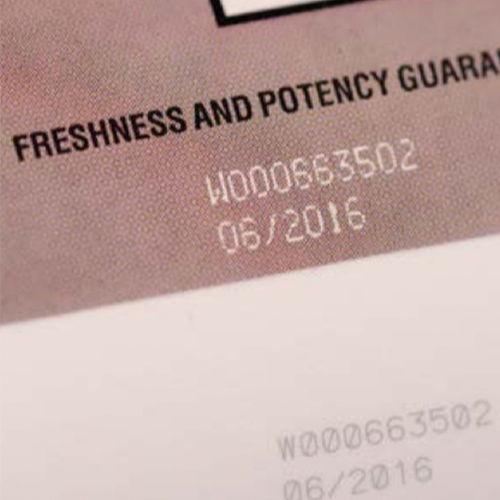

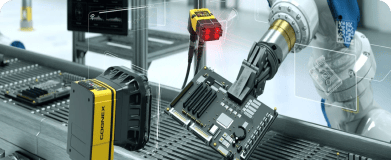

Laser marking is a process that uses a laser beam to engrave or mark surfaces. This technology is characterized by its ability to create permanent marks without direct contact with the material, making it especially suitable for industrial environments.

There are several industrial laser marking methods:

- Ablation Marking: Removes surface layers of the material to create the desired design.

- Annealing Marking: Changes the surface color through thermal treatment without damaging the structure.

- Deep Engraving: Produces tactile marks, ideal for parts exposed to wear.

8441124288

8441124288

844 278 5462

844 278 5462